Manufaturing and Processing

When you are searching for the proper Silicone Rubber component manufacturer with stable quality but optimized cost, LIKAYO is an exceptional choice. LIKAYO, which has the integrated capabilities of processing and selling, can save your time significantly. We have a multi-category series of silicone products for you to choose.

For customed solution, we attemp die sinking precisely according to the design diagram or incoming sample, evaluate the proper molding processing, then produce fast with excellent quality control. A few samples can be provided for testing before high-volume manufactring, if necessary.

For the Liquid Injection Molding, LIKAYO requests that all molding cells deliver consistent shot-to-shot quality from the first LSR part to the last. As for the compression processing of solid silicone rubber, experienced workers strictly follow the procedures to produce compliant products in the steps of mixing, turning, coloring, and weighing. LIKAYO could operate large orders and fully guarantee the delivery time, due to the higly-automated possessing , efficient silicone parts manufacturing capabilities. Under the class 101 production environment and quality control, our silicone products comply with various strict standards such as PDA, CE, CPC etc., and meet the quality certification requirements of most countries in the world.

As the professional LSR producing partner, there is no one but LIKAYO meets your manufacturing requirement, , and no one is more experienced in helping customers make the most of LSR.

Design and Development

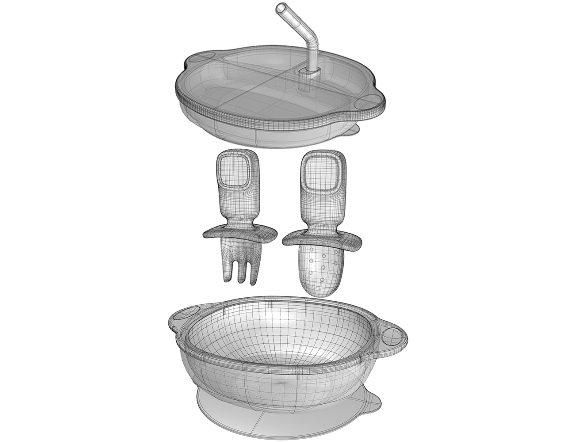

In response to customed needs, we can provide customers with design support to achieve optimal manufacturability and parts performance. Usually, before long-term production, prototypes are needed to undergo the evaluation of specification and dimensions, assembly relationships, function, as well as clinical trials, inspections and trial production. The reason to test the prototypes is to avoid products defect in performances of elasticity, toughness, transparency, strength, flame retardancy, temperature and weather resistance, adhesion etc..

Considering the three factors of time, cost, and quality, there is a variety of prototype methods. For a small number of parts, you can choose 3D printing LAM technology; when the number and quality of parts are slightly higher, you can use molds to produce LSR parts; when you need to produce high-quality LSR injection molded parts, you can choose to trial production under actual production conditions and build fully automated production at the same time. Our team of experts and rich experience can help customers achieve the optimization of product quality under the condition of reasonable cost control.

Quality Control

LIKAYO has the ability to meet stringent requirements, so that LSR injection molding always meets the most stringent quality assurance standards. Whether in any process of product design, tooling, prototype design or new product manufacturing, LIKAYO always lists quality control as an important parameter. During the processing, LSR parts are under continurous monitoring for defects, damage or any other inconsistencies; a database control code is marked on the materials of each manufactured part; and a traceability system is established to track the production date of each product, the manufacturing processing and the materials used.

One Stop Service

LIKAYO integrates the advantages of a professional foreign trade company and a factory. It can not only guarantee the supply of goods, arrange customers to visit the factory, connect product details, supervise the production progress, but also has professional export trade experience, so that the customer's procurement process is simple and convenient.

We are also Amazon sellers supplier, support printing item label and customized packing, send to Amazon warehouse for FBA with DDP.

LIKAYO is located in Xiamen, one of the first special economic zones in mainland China to open to the outside world, and one of the country's four major international shipping centers. Geographically, it has a favorable business environment extending in all directions. Xiamen Port covers 129 ports in 48 countries and regions around the world, and there are 92 international container liner routes. Xiamen is the only land-sea hub city in China that realizes the seamless connection between "One Belt" and "One Road". It has opened international freight trains to Europe, Central Asia and Russia, mainly to 12 countries and 34 cities.The superior environment creates a well-developed comprehensive foreign trade service, which can be implemented in one stop for customs clearance, foreign exchange collection and settlement, international logistics, export tax rebate and other services.